-

Posts

308 -

Joined

-

Last visited

-

Days Won

1

Content Type

Events

Profiles

Forums

Media Demo

Everything posted by alxzinbox

-

The 3d model has to be first built using a 3d software like Blender (free). In my case I construct it using the measurements from the kit, and detail it using blueprints, photo and video references. Trawling thru the Walkarounds here on Britmodeller were invaluable in imparting a lot of insight to the design and shapes of the components. This digital 3D model is then "sliced" into a stack black and white images, each representing a cross section of 0.01mm in height of the model which looks like this. The resin printer then displays the image using a UV led screen which cures a thin slice of the liquid resin. This video will better explain how it works : While some might scoff at you, there are ways to convert a 2d image into a 3d model. It's pretty convoluted and technical (even for me) but it's possible. Phones these days have apps where you can take photos of an object from multiple angles and it'll create a rough model in 3D that you can scale up or down as per your needs (for eg. you can scan and miniaturize a barrel to insert into your diorama, or enlarge a rubber ducky to use as a lawn ornament) Cheers, Alex.

-

Epic shot!!!

- 30 replies

-

- 2

-

-

-

- Tamiya

- F14 Tomcat

-

(and 1 more)

Tagged with:

-

Hi there, After a long hiatus of almost 2 years, I'm super excited to showcase some work-in-progress of my Airfix 1/72 Sea King HAR 3! I picked the kit off the clearance shelf of a big box store, with the intention of doing a quick weekend build to get the momentum going. As everyone knows, that never happens. All Airfix kits deserve a loving round of riveting to elevate the model to greater heights. More so on the Sea King with her prominent (albeit raised) rivet detail, that will later serve as a blueprint for weathering. Next up I decided that the Kit Landing gear wasn't detailed enough for my taste. So I went about modeling the landing gear in 3D with intention of 3D printing it. I modelled the gear in both extended and weighted modes, as the model I'm building will be in flight Same with the wheels and tires. The kit comes with weighted tires, and I gotta say are equally detailed as the 3d Print. I however needed unweighted tires for the extended landing gear. So I went ahead and modelled it. Made a weighted tire as well just for the heck of it. Next up I tried to drill a hole into the Sand Filter exhaust. I ended up ruining the part, and as my efforts to find a replacement tube in correct scale failed, I went the 3d Route again. With the kit part on top: There is a significant bump in detail quality, unfortunately the part seems over detailed to the otherwise simplified detail the starter kit provides. Next I turned my attention to the hydraulic winch. The kit struts seemed a little too thick, and redoing it using styrene rod seemed like a challenge I wasn't upto anymore with my failing eye-sight. So 3D modelling it was... And the final result: The 3d printing layers are magnified due to macro lens. At scale length, it's hardly visible if at all. My only concern due to the in-scale but now fragile struts is Moving to the grand finale (at least for me at this point of time), Since the bird will be in flight, the kit rotors would need significant modifications to work as I envision it to be.... So I spent a SOLID 10 days poring over thousand images and a few videos to make some sense of the complicated main rotor head. After multiple false starts, I was finally able to complete the model and print out a test print. Incidentally, each rotor arm is different from the other (due to the folding mechanism) , and not just a simple job of radially copying one completed arm 4 additional times. Again, the print layers are visible below due to the macro lens, but almost invisible as seen above. The alligator mouth are 3d print supports to hold up the upper plate of the blade fork. They will be removed in the final installation. I had modelled attachment points for hydraulic cabling using copper wire. It remains to be seen how well that idea will work. It'll be unfortunate to have raised the bar this far only to drop the ball at the last stage.... so I'm going to hydraulic line this bad boy, no matter the cost. Next will be the rotor blade attachment tests and the tail rotor (which is in currently being built in 3D) Will update in a bit. Thanks for watching! Cheers, Alex.

- 40 replies

-

- 38

-

-

-

Supermarine Spitfire Mk.I (early), Airfix 1/72

alxzinbox replied to Serge Tkach's topic in Ready for Inspection - Aircraft

The riveting is outstanding. I had to do a double take whether Airfix had released a spitfire with riveting. It looks factory perfect.- 37 replies

-

- Supermarine

- Spitfire

-

(and 1 more)

Tagged with:

-

F-18A Hornet - BUNO 162875 - Adversaries

alxzinbox replied to Eagle57's topic in Ready for Inspection - Aircraft

That is so cool. I've never seen people so close to a flying F-18 before this, and it's so dramatic! Only possible with a model. -

My 72nd scale collection 250 finished models

alxzinbox replied to Zoran Srb's topic in Ready for Inspection - Aircraft

How many lifetimes have you spent building this collection? I could probably do one shelf in a lifetime at the quality that you've built your entire collection at. -

Didn't know you get these huge super-sized Tamiya Extra Thin Cement bottles... your 72nd scale Thunderbolt is outstanding! oh wait......

-

Resin printed 737-200 - First attempt

alxzinbox replied to A300F's topic in Ready for Inspection - Aircraft

That's amazing! Impressive weathering even at the 1/400 scale! I'm dipping my toes into resin 3d printing as well, and it's unbelievable! You mentioned sanding- Did you turn on anti-aliasing in your slicer? I resin printed an exhaust, and the difference in smoothness with anti-aliasing on and off is HUGE. -

Are you sure that this is in 72nd scale? 😲 That landing gear is insane! Everything actually!

-

MiG-23 UB of the East German Air Force

alxzinbox replied to dragan_mig31's topic in Ready for Inspection - Aircraft

Great work! The youtube video perfectly illustrates the hard work gone into making it look as good as it does! R.V. does require a LOT of sanding- 31 replies

-

- 1:72

- R.V.Aircraft

-

(and 1 more)

Tagged with:

-

Great models- Love the photography too!

-

Revell 1/72 F14D NE106 of VF-2 "Bounty Hunters"

alxzinbox replied to SaminCam's topic in Work in Progress - Aircraft

Looks amazing- love how those exhausts turned out. -

Eurofighter Typhoon, Hasegawa 1/72

alxzinbox replied to jarkmodels's topic in Ready for Inspection - Aircraft

That's a beauty! The weathering is so subtle, yet convincingly portrays a well used and well maintained aircraft. The bare metal is noteworthy. -

Eagle eyes!! You're right- the aircraft was supposed to be build with wheels dry and the torpedo attached. So the shackles were already glued to the torpedo prior to painting. Unfortunately they got destroyed while cuttting them off. Of course, this is a grandiose excuse for not scratch building them. Thanks, Alex.

-

That's a beauty! The riveting makes all the difference in the final outcome doesn't it!

-

Hey all, Here's my rendition of the excellent Airfix 1/72nd Bristol Beaufighter TF.X Built OOB with added rivets to fill up the large panels. I initially planned it wheels down on an airfield. I changed plans midway to depict a moment over the Channel just after the torpedo was dropped. Unfortunately mods like a head turn on the pilot, and various pitches in the control surface and the tail wheel in landing config were too late to change as I had already built and painted the model by then. Also my resident elf 'Sloppy' decided he wanted the tail gunner's machine gun for himself. It was also an experiment with liquid resin. Modeled the ocean with Plaster of Paris, made a negative with latex rubber and then poured the resin. Messy! The splash was made with cotton and white glue (also hides the deployed tail wheel and acrylic rod holding the aircraft up) Unfortunately the torpedo and all the work with the bubbles is hardly visible in the end result. The props were made by masking and spraying the black and yellow in two separate passes on clear packaging plastic. They're pretty flimsy- I need a better solution for that. Painted with Tamiya acrylic, Alclad2 Burnt Iron on the engine cowling and weathered with oils and pastels. It's a surprisingly large aircraft with a wider wingspan than the F/A-18F or Sukhoi-30! WW2 was a crazy time in engineering ingenuity. Thank you for your interest! Cheers, Alex.

-

A-4F Skyhawk "Blue Angles" 1/72

alxzinbox replied to Han Solo's topic in Ready for Inspection - Aircraft

Beautiful! Good choice on the dropped flaps. Contrasts nicely with the blue -

Thanks Alex- I've been an admirer of your airliner builds on this forum! You're right regarding the windscreen. I had to sand it down some to get a better profile. There is a spare decal in the kit, so I'll try cutting the decal into individual windows. Wish I'd thought of that earlier. Cheers, Alex

-

Thank you so much Ian! I've really admired and have been inspired by your airline models, especially the venerable 747s. Why didn't I think of cutting the decals to get them fit better. Thank you for your kind offer for the decals. Really appreciate it. Fortunately the kit has a 2nd set of window decals which I will try. Cheers, Alex.

-

Hey all! My first civilian airliner model! What better subject than the classic Indian Airlines black nose Boeing 737! I grew up near the Santa Cruz Airport in Bombay, India in the 80s. Many afternoons, I'd go running to the terrace to watch these noisy aircraft take off from Runway 32 towards the Arabian sea. That and the logo of the Indian Airlines will always stir up nostalgia. The registration VT-EGA is fictional (The GA being a reference to my homeland Goa) This was the first time I printed out my own decals (for the lettering and serial numbers) The tail logo was masked and painted. The cockpit decal wouldn't set properly and is slanted upwards. Also please ignore the missing panels on the landing gear Cheers, Alex.

- 16 replies

-

- 33

-

-

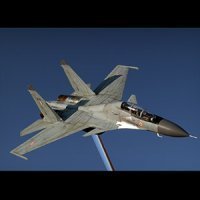

Su 27UB 1/48 Great Wall Hobby + Quinta Studio 3D

alxzinbox replied to Bobek's topic in Ready for Inspection - Aircraft

😲 Jaw droppingly AWESOME! Those burner cans and weathering are perfect -

All your builds are flawless! always a pleasure

- 26 replies

-

- 2

-

-

-

- BOEING 747SP

- Eastern Express

-

(and 1 more)

Tagged with: