-

Posts

308 -

Joined

-

Last visited

-

Days Won

1

Content Type

Events

Profiles

Forums

Media Demo

Posts posted by alxzinbox

-

-

Quote

1/72 Sword SeaStar

8 minutes ago, Ad-4N said:I shoot all my models in outdoor light. I didn't know the technical reason why they looked better, but they do:

1/144 Minicraft 707-327C

1/48 Hasegawa Hurricane

1/48 Monogram NF-4D

1/35 Tamiya Sheridan

1/72 Hasegawa Marauder

1/144 Roden C-141B

1/144 Minicraft 727-222

1/72 Sword SeaStar

1/144 Minicraft C-135A

Using Glass on the Sea Star is such a clever way to simulate a flying model!

Your work (and the tarmac base you photograph your models on) is spectacular-

1

1

-

-

On 3/20/2024 at 4:25 PM, scautomoton said:

Stunning effort! Regarding the motion blur efforts and the drooping of the blades, maybe a possible solution would be to print with a channel along the length of the underside of the blade that could have a metal rod (spring wire perhaps) glued in place, then filled over.

That is a really good idea. I do intend to give it a 2nd shot on a future project (it was holding up this project for way too long and staying rent free in my head)

23 hours ago, Captain Glumbo said:The starter kit is currently £16 in their spring Sale (+10% member discount if you're in t'club, so £14.30). Not as cheap as CAD$10 however. I ordered mine today but no way will it be anywhere near the quality of your build! Well done!

I'm only on my 3rd build (De Havilland Vampire T.11) which hasn't come out too bad, but the Sea King will be later in my stash once I've had more practice at airbrushing et al (the Vampire was my first airbrush attempt).

Do you have the Vampire up on RFI ? I got lucky in that the store wanted to get rid of it's non-sellers. But even at GBP16, it's awesome value. All their newer kits are an absolute joy to build. If you're going to do the Rescue Yellow, just make sure you prime with white and save yourself a LOT of pain

22 hours ago, Ad-4N said:Incredible detail. Natural light photos are the best.

100%. I work in the movie VFX industry, and all realistic CG work includes a "HDRI" reflection to make it look like it's in the real world. That reflection is something that's missing in an indoor photoshoot. You get that for free outdoors with real models, so it's a no-brainer. You do need an open space though with maximum sky visibility.

-

1/144!!! Looks great in RCN colors. It's a coincidence I was checking out the AFV's site today and was thinking I should pick one up to compliment my 1/144th collection.

I'd reckon the lack of detail in rear would be irrelevant as you can see precious little even in 72nd.

It'd only make sense if you installed an LED to showcase the detailing done within.-

1

1

-

-

On 3/15/2024 at 1:33 AM, AdrianMF said:

Absolutely wonderful! Meticulous detailing, immaculate finishing and atmospheric photography.

My only question is why a girl with a broken leg and arm should have decided to go hill walking in the first place?

Regards,

Adrian

haha.... very valid point. Maybe one in her group just happened to be a orthopaedic assistant, and for some reason had the full fracture casting kit as well as a foldable crutch in her backpack. Pumped full of adrenaline and morphine, she's probably dreamwalking to the helo. Thanks for the kind words!

On 3/15/2024 at 9:02 AM, twinpin said:Absolutely brilliant.

Is this particular Airfix kit a good one? I think with some versions of the kit the rotors are not so good ?..

Thanks! I believe it's a relatively new tool, so goes together like a charm. I did assemble the kit rotor, and it was pretty good albeit basic. The only caution with the kit would be to taking your time to get a good fit of the clear canopy to the fuselage.23 hours ago, FIGHTS ON said:Amazing build from the airfix kit that so many of us are familiar with. Thank you for taking the time to post the images and the work-in-progress. Even getting a decent yellow finish is a challenge for most of us!

As Jonners states, there is no surprise with what some people do or wear in the mountains in the UK. Flip Flops & t-shirts isn't out of place on the Welsh mountains it would seem - although I like to think of it as Darwin's natural selection process at work.

I have helped my son set up his 3D printer and the results are pretty amazing. I haven't yet had the time to learn how to make my own parts, so I use some of the various websites that either sell (or offer for free) some of the .stl files. (website selling GBU-24 .stl file) I know I am 1 of hundreds that are desperate to find a decent 1/72 sandbox filter.....maybe your path to becoming a multi millionaire lies in cornering the market!.....actually, learning to use Blender has just crept up my list of urgent things to do !!!

Thank you! 3d printing is the next best thing after CAD model kits in our hobby. This build was a test bed of sorts to potentially start a line of detailed parts. Let's see where that leads. Blender is a beast for creating your 3d parts. You can really enhance kit parts by throwing together basic shapes (Cylinders, boxes and tubes) like you would in a scratch build. I've seen some youtubers use tinkerCAD as well, which seems to have a smoother learning curve to Blender.

6 hours ago, Robertone139 said:Excellent work and amazing 3d printng, are those items your own or did you have them done on contract?

Thanks! I 3d modeled the items over the months using kit parts for dimensions and reference photos found here on Britmodeller and the rest of the internet.4 hours ago, Sky Keg said:Impressive in so many ways. Yellow is by no means an easy color to work with yet it has been applied evenly. Weathered to perfection. Very nice.

Mike

Thank you! The secret to a good yellow finish is a white primer and preshading in a light brown. You don't want any greys or blacks below your yellow.-

2

2

-

1

1

-

-

So good! The chosen scheme ties contrasts nicely with the base and figures.

-

1

1

-

-

The weathering on the camo looks like you snatched and shrunk the aircraft right off an airfield. Love the chipping effects on the baremetal engine cowlings too

-

1

1

-

-

Build completed. She won't be flying anymore. Rotor prop blur just too damned hard.

-

1

1

-

-

- Popular Post

- Popular Post

Hey All,

I found this kit in the clearance bin at a Canadian Tire- overlooked and unwanted, and most importantly for just C$10.

I started on it way back in August 2023 as an quick weekend attempt to break out of a 3 year long modelling dry spell.

The detailing devil crept in starting with a riveting pass. Having recently purchased a 3d printer, I took on the challenge of modeling and 3d printing out the landing gear, main rotor head, tail rotor, hydraulic winch, sand filter and other bits and bobs around the aircraft. The build thread can be found here.

The success of the build is largely in part due to the wealth of reference photos here at britmodeller.com. I also received a lot of helpful suggestions and hints, and even some in-depth knowledge of Sea King operations from user Jonners in the build thread. Hugely appreciated!

I initially planned on modelling the helicopter in flight with rotor blur, however main rotor droop was a problem that I was unable to solve despite multiple tries over as many months. I finally bit the bullet, downgraded plans and posed the helicopter on the ground.

Decals were from the kit, along with PRINT SCALE decals for the 202 sqn logo, and ZE370 serial number from spares

Spring has come early with gorgeous golden hour light, perfect for photography. The (real) grass is still dormant though

I used AK's Hyper Thin Rigging line for the antenna rigging. This particular aircraft had sea grey on the port landing gear with a white hydraulic actuator, and white on the starboard landing gear.

Painted with Tamiya X-8 Acrylics and weathered with oils. Preshading on the rivet lines was done in brown over a white primed plastic

Scratch built rear view mirrors. Antennas on the bottom made using fishing line

3d printed tail rotor, and static discharge rods using fishing line. Ventilation grates on the tail boom were added using wire mesh inserted in cutouts in the plastic

Figures posed from purchased pilot figures. Injured woman downloaded for free from cults3d.com

Black caulking on the pontoons made using a fine tip marker. Red emergency release tabs on the windows were made using Enamel paints.

3d printed rotor head with cabling and cap. Handles on the air intake hatches made with copper wire.

Handles above windows made using copper wire. The grey trim around the cockpit windows was painted with enamel grey that allowed for sharp outlines (using enamel thinner to wipe the imperfections away)

3d printed winch. Hook from kit part. Steel cable from fishing line

3d printed landing gear and wheels/ tires. The landing gear was installed in the un-weighted position due to the 'lofty' plans at the beginning of the build. However, they were glued in place and I was unable to switch to the weighted landing gear after grounding the build.

3d printed sand filter, and wire mesh for the grates installed after making appropriate holes in the plastic. Looks way better than the supplied kit decals.

Some images of the 3d printed detail parts:

Motion blur effect on the tail rotor tests

R

What a difference a riveting pass makes. Worth the extra effort.

If you've made it this far, here's an image of the rotor blur tests I did:

note the warpage in the rotors. It got progressively worse within a few hours.There was a sense of relief in completing this build, more than a sense of accomplishment and joy. Sitting unproductive on a project for months does that to you. Good thing is that the mojo is back, and I've got some other fun projects (albeit without the 3d printing) on the table now.

Thanks for watching!

Cheers,Alex.

-

72

72

-

4

4

-

Top notch! Loved all the detailed weathering

-

1

1

-

-

That's a great build! I had to bin mine due to the mating of the forward fuselage into the main fuselage. Your seam in that area is non-existent! The overall weathering is really good too.

-

1

1

-

-

WOW!! Your build looks REAL! very inspirational

-

1

1

-

-

Outstanding build, weathering and photography! Bet you were pushing the f-stop to the max

-

The main rotor blades are less successful, primarily due to the additional thickness of the motion lines. I initially added some upward bend to simulate the hover effect, but combined with the lifted armature of the rotor head, and the curing bend, it's now too much....

I struggled with the hydraulic lines on the rotor head and finally called it quits after the little i've done. I don't think I'd want to go thru that again on a 2nd attempt at the blades.

Calling this done for now, and moving on to the diorama itself. Now to hunt from some beautiful rocks (easier said than done when you live on a former mud plain)-

4

4

-

-

3d Printed and painted the blurred tail rotor. A few printing errors (no idea why)

A lot of fiddling around with super-glue to get the small contact area to join perfectly and this is looking pretty cool in real life (the close-up macro lens does reduce the effect highlight a lot of flaws)

Now on to tackling the challenge of the main rotor blades....-

3

3

-

-

Made another variation of the rotor blade blur with more 'teeth' and on both sides of the blade

The print for this is in progress at the moment with a few hours to go.

I also redid the tail rotor blur to match the style of the main rotors. Creating supports for this will not be as straightfoward, but the end result atleast in 3d looks pretty sweet with some colors slapped on it for fun. Had to share!

The next update should hopefully have the rotors installed on the aircraft! fingers crossed!

Alex.-

4

4

-

-

Stellar work so far Perdu! Those hydraulic lines complete the resin engine. Great job

-

1

1

-

-

3 hours ago, heloman1 said:

An interesting approach to the rotor blur. I hope it works.

I didn't come up with this idea myself. I'm heavily borrowing ideas from others on this site, as well as the possible original creator https://www.propblur.com/store/c1/PropBlur.comMainOn 12/8/2023 at 12:07 PM, perdu said:Do you know I meant to produce a cone and cut away the centre to allow you rotor head to interface with it under the model?

Got the Acetate sheets today. Will spend some time this weekend creating a jig that I can install on a power drill to airbrush the blades on. I hope simple masking will be sufficient for the blade tips and the lone yellow blade.

-

1

1

-

-

2 hours ago, perdu said:

This could actually be the best solution. The cone shape would hold the lifted orientation of the blades, and airbrushing the transparency would be the easiest thing to do. The seam could be hidden inside one of the blades. Amazon has some 12"x12" sheets which will work perfectly for the scale.

Thank you for the idea!!

I tried this approach to rotor blur, I'm not the biggest fan of the comb shape though. This can however be printed in the more rigid grey primer. Will put some test prints down tonight. I wonder if the style will match that of the tail rotor

-

5

5

-

-

7 hours ago, perdu said:

alxzinbox have you considered moulding a transparent disc in acetate or PETG with a conic section pulled into it as a rotor disc in flight?

Blade droop is exactly what you don't need here isn't it?

Jonners is dead right about how good yours looks so far, indeed I'm stunned by how good the tail rotor is for example, I'm going to wish I had one of those filters for my HC4.

(interaction from previous users is a characteristic of Britmodellers, we have some wonderful people sharing our hobby-space in here don't we?)

Hello Perdu, thank you for your reply

I used acetate discs on my Bristol Beaufort rotors. I had considered it on the Sea King as well, but a disc wouldn't sit right with the 3d printed rotor head with the individual blade arms.

My next attempt will be blades printed out in grey resin which is less prone to droopage, and while the shape will be very similar to the kit blades, I plan on adding some motion blur lines to trailing edge. Not sure how that'll look, but it's the only hope left for portraying a moving blade.

Oh yes! the community here on Britmodeller is amazing as seen in this thread and a multitude of other threads. In fact a lot of my research was based off walk-arounds of the Sea King from the relevant section on this site.-

1

1

-

-

18 hours ago, Jonners said:

Yup. 2100 hours flying Mk3s. It's coincidentally on the top line here, in a pic I took to illustrate another airframe's appearance (XZ597, operated in airworthy condition by Historic Helicopters):

'Airtest post ASE pack change' refers to an airtest following the replacement of the Auxiliary Servo Equipment assembly, in other words the aux hydraulic rods that were contained in the floor-to-ceiling box immediately behind the right-hand (P1) pilot's seat and opposite the crew entry door, referred to as the 'broom cupboard'.

That's so cool!! I'd never imagined that an actual pilot of the aircraft I'm modeling would reply in the comments. I'm honored!

Thank you for reaching out!-

1

1

-

-

22 hours ago, Jonners said:

ZE370 appears several times in my logbooks!

Jon

....as in you actually flew that bird?! 😲

-

47 minutes ago, eng said:

could you 3D print these with a groove along the full length that would allow you to insert a fine length of steel with to help give the correct bend in the blade? Just a thought.

The rotor blades I printed out in transparent resin quickly deformed and went all limp and floppy like an unwatered plant

so your idea is solid.

so your idea is solid.

Executing it in 72nd will be tough unfortunately due to the limitations of resin drainage and curing of a long tube during printing, so I'll probably have to try a different approach with the regular grey primer. It should be possible in 48th and above.

Thank you for your interest. I'm still testing the feasibility, and once I have a working prototype I will definitely put these up on sale.-

10

10

-

-

Slow progress...

Modelled and 3d printed the tail rotor to detail the kit part. I elongated the blades and printed it out in clear resin and airbrushed a gradient on the blades to simulate motion blur.

I elongated the blades and printed it out in clear resin and airbrushed a gradient on the blades to simulate motion blur. Will detail paint the rotor hub by hand

The main rotors are proving to be slightly more challenging due to blade sag. I'm not sure that I will be able to solve that with my existing experience. I've had to thicken the blades to stiffen them, but that added on more load. Now I've got brass rod connecting it to the rotor head assembly.-

14

14

-

-

What a smooth and crisp finish! Well done

-

1

1

-

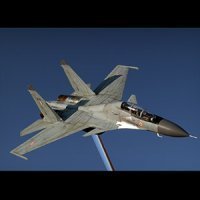

GWH 1/72 F14B Tomcat

in Ready for Inspection - Aircraft

Posted

Always a pleasure seeing a Tomcat. Looks great. The subtle shaded weathering and the metal colors are perfect! The kit is quite a detailed beast. Kudos on wrangling it to such a finish!